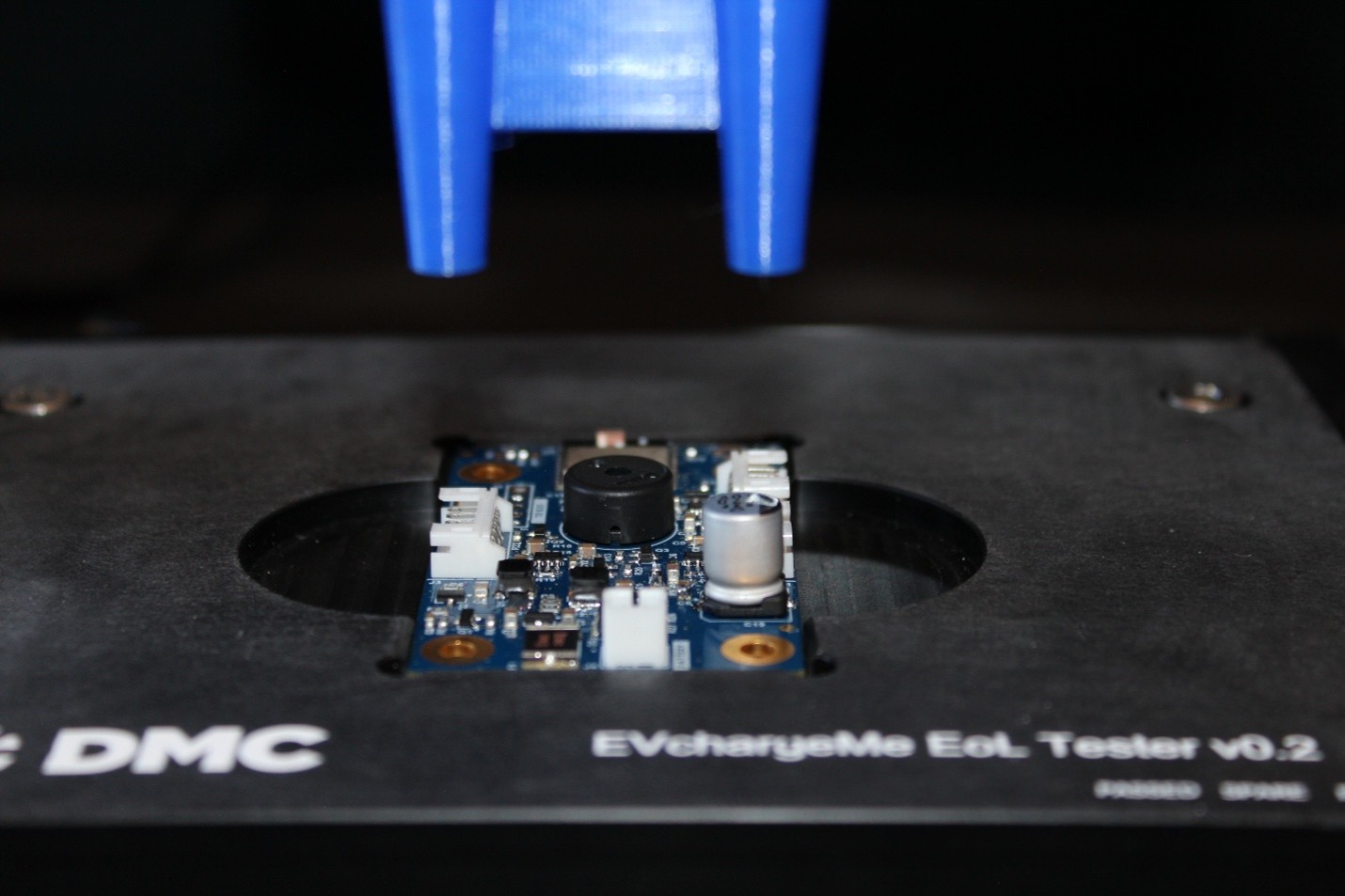

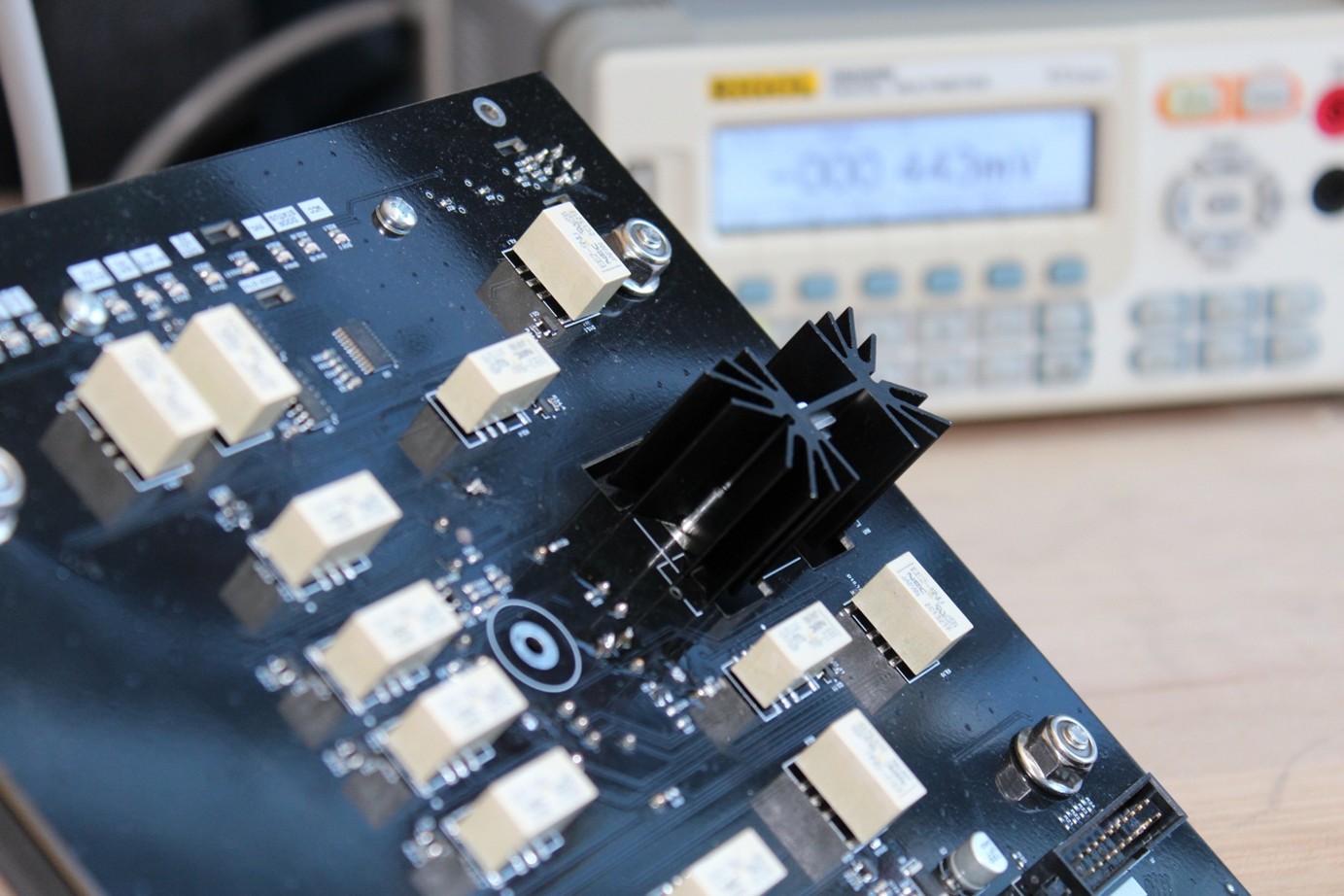

The EOL tester is designed to verify the integrity and functionality of the Wireless Lockbox Controller before it leaves the production line. The system consists of a bed-of-nails (BON) test fixture that makes electrical contact with key test points on the DUT. Once the DUT is placed into the fixture, the test sequence begins at the push of a button. The test sequence is fully configurable and could include a number of steps, for example:

- Initial Power Test – Ensures the DUT powers are on correctly before programming.

- Program MCU – Flashing firmware and updating security parameters.

- Full Power Test – Verifies power consumption under normal operation.

- External Peripherals Test – Emulates internal/external sensor signals and performs actuators tests to ensure PCB functionality.

- Provision DUT – Configures the DUT for deployment, applying final settings.

By implementing this automated EOL tester, our client significantly reduced the risk of shipping defective products while increasing production speed and efficiency. The system’s reliability and scalability ensure it remains a valuable asset as the company expands into a very competitive EV market.

Need an automated test solution for your production line? Contact DMC today to discuss your requirements!

Learn more about DMC’s EOL Testing systems or other embedded solutions and contact us for your next project.