The client chose DMC to help automate a complex assembly machine with a fast-approaching project deadline. DMC handled the full software implementation including PLC development, HMI screens, robot programming, motion control, and commissioning.

The system consisted of two PLCs: one that controlled the assembly portion of the process and one that controlled the packaging.

Assembly Machine:

- SuperTrak conveyance connecting 11 stations

- Assembly of input components by drives and pneumatic actuators

- Denso robot part handling

- Operator HMI for system monitoring and manual operations

Packager Machine:

- Denso robot part handling

- Servo motor-controlled tray handling.

- Interface with assembly machine

- Operator HMI for system monitoring and manual operations

Each machine had its own PLC program that was created using Rockwell’s Logix Designer programming environment. To coordinate part handoff between machines, the two PLCs communicated to each other through produce/consume tags.

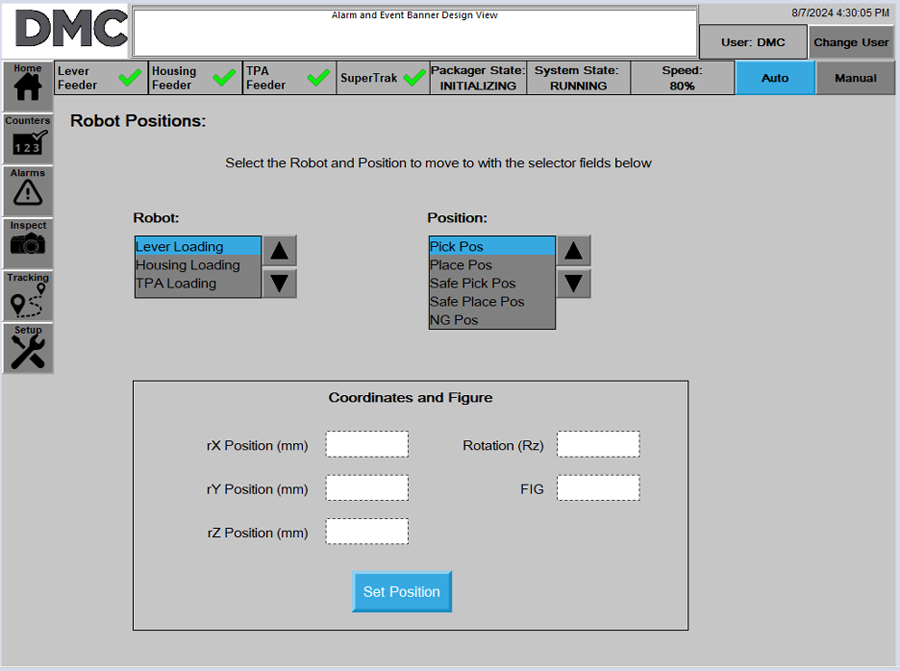

Assembly and Packaging Machine HMIs

DMC programmed HMIs for the assembly and packaging machines using FactoryTalk View SE. Each HMI displayed common information about the state of the system, information specific to assembly or packaging processes, and dynamic graphics to show the status of devices interfaced with the PLC. System warnings and faults detected in the PLC and robot code were displayed on the HMIs using descriptive alarms, which decreased the need for monitoring of the system.

Standard Architecture

DMC began work by creating a standard architecture to be used by both machines. The architecture was structured around Pack ML (ISA-TR88). This predefined structure helped ensure that the machines could properly transition from a stopped state to a running state in an organized manner. The consistency provided with Pack ML also helped ensure that the two machines were properly coordinating their operations together.

A safety program was created to minimize any risk to machine operators. All system motion could be stopped by any one of the E-stops on the machine or if any of the doors of the system were open during machine operation. To allow maintenance staff to accurately diagnose any issues that might come up on the machine, DMC programmed controls allowing some limited system motion when the machine’s doors were open. This feature could be activated by turning a safety rated bypass key switch.

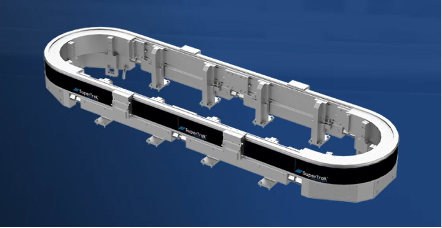

SuperTrak Conveyance System

Much of the Assembly Machine’s operation centered around its SuperTrak Conveyance system. For this project DMC utilized SuperTrak’s TrakMaster software to configure the track behavior and created PLC code to integrate the track with the rest of the system. In order to meet the aggressive performance target from the client, DMC had to finely tune the SuperTrak system to minimize part transit time and reduce track overheating.

Parts were loaded onto the track using three Denso robots. DMC programmed these robots to pick incoming parts up and move to the track in an optimized path to maximize the throughput of the line.

Keyence vision systems were used to inspect parts at several points in the assembly process to verify that the parts were acceptable. Any faulty parts would be unloaded into a bin for analysis.

Once parts were fully assembled, a fourth Denso robot would use a vacuum gripper to pick it up from the track and move it to the packager machine. There, the packager would organize the parts into trays and then stack those trays together once they were full. The stacks were then moved onto a conveyor, which made for easy and efficient operator unloading.

DMC’s experience allowed us to successfully provide the client with a robust completed machine that had a high throughput rate all within a strict project deadline. The preparation done in defining a robust system architecture made the commissioning process smooth and efficient. This also kept the programming from becoming unwieldy, even when controlling a wide variety of devices.

Learn more about DMC’s Rockwell Programming expertise and contact us with any inquires.