So, you either had a system that was working and then a red light showed up, or you bought a used PLC and the fault light showed up. Here's how to fix the fault light.

If the "BATT" Light is Red

You should replace the battery within a few days. You should keep the PLC running since the PLC will lose the program if it loses power for more than a few minutes without a battery (check your PLC manual for how to do this). If it's been red for more than ten days, you probably have a dead battery and may have lost your program if the system is no longer working. Read ahead to learn what to do.

If the "PROC" Light is Red

You have a processor fault.

- If blinking red, you have a run-time error.

- If steady red, you have either a RAM error, memory module error, or internal diagnostics have failed.

Check that the keyswitch is either in "RUN" or "REM" position. These positions run the code on the PLC. Move the keyswitch to "PROG" (this stops the code on the PLC) and then back to "REM"/"RUN". Chances are this won't fix your problem, as the code on your PLC-5 has been working fine for years (possibly decades) and you have some deeper issue going on.

As a sanity check, check that all the communication cables to the PLC are good, that the modules all look good, and that the input memory card is inserted correctly. Consult your PLC manual and make sure qualified personnel make these checks as making mistakes could fry a card, or cause injury to someone who is unaware of electrical dangers in the cabinet.

As a final check before going further, was this a replacement PLC that you just put in the rack? If so, the PLC does not have your code on it and you will need to learn how connect to the PLC and upload your code. If you do not have any code, reach out to us as we've been able to write new code for systems using just a functional specification and I/O sheet.

How to Connect

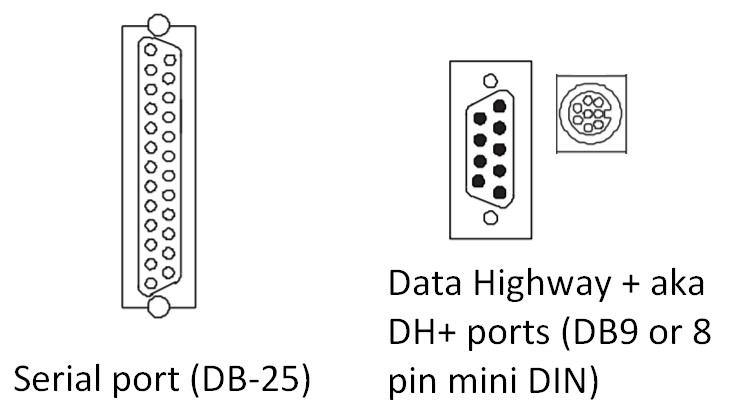

You'll either have a serial port connection, or a Data Highway + port on your PLC. Both types shown below.

I would recommend connecting through the serial port if you have one, as connection adapters for Data Highway + ports are around $2,000. You can make your own serial connector for less than $50. If you do not have a serial port, I recommend contacting Rockwell and following their instructions on how to use their Data Highway + device. The instructions below are for connecting via serial

- Connect a DB25 (male) ->DB9 (female) cable ($10) on the DB25 (female) port of PLC5

- Connect the DB9 (female) end of the cable to the DB9 (male) port of a USB to Serial adapter ($30, we use the USA-19HS Tripp Lite adapter)

- Connect USB adapter to PC, and ensure it has a comm port in Device manager

- Open RSLinx Classic and add a new driver (communication->configure drivers)

- Select RS232-DF1 device, add new

- Rename if desired, then change comm port to the one in device manager, and select "Auto-Configure"

- Hit OK when configured, and close out of RS Linx

- Open RSLogix 5 Pro and go to Tools->Options->SystemCommunications to make sure the driver you just set up is used.

- [Optional] Within RSLogix 5 pro is Comms-> Upload (upload from PLC to PC, do this to see the code on the PLC) or Download (download to PLC from PC, do this only if you have new code on your PC that you want on the PLC)

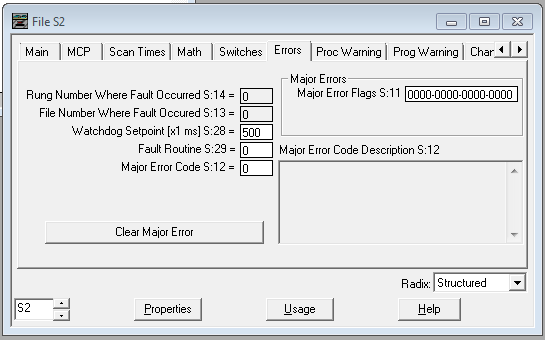

At this point, you're online with the PLC and can upload, download, or view errors. If you right-click the PLC and look at the properties, one of the tabs is the list of errors on the PLC. This is where you can learn exactly what is causing the red light on the PLC, and even clear it in some cases.

Based on the error code given, you can look it up in your manual or on the internet. From there, follow the recommended solution!

Learn more about DMC's Allen-Bradley PLC programming expertise.