DMC regularly implements successful project solutions using Siemens PLCs. Along the way, we've learned a few quick tips that can save hours or even days of time in post-project support. If you're working on a project using a Siemens 1200 or 1500 PLC or a WinCC HMI Panel, make sure to consider these three steps below. Each one takes less than five minutes, but can help you avoid undesired post-project consequences and can make testing much easier.

Switch Your S7 PLC to Run on Startup

A Siemens S7 PLC project’s default startup setting is to return to the mode it was in before power off, and this can be an issue when downloading a finished project directly to a PLC and expecting it to RUN on startup.

Out-of-the-box PLCs come in STOP mode, so if you download a validated project to a PLC and expect a user to be able to run it without using TIA portal development software, they will need an external way to switch the PLC into RUN mode.

For 1500 PLCs, this can be done using a switch on the front panel. However, for 1200 PLCs, there is no onboard way to turn the PLC into RUN mode. That means that 1200 PLCs with default startup settings will be stuck in STOP mode until you can connect to them via the TIA Portal Software or using a web server (explained below).

Luckily, the fix is to configure the PLC to jump to RUN upon system startup. That way, users without access to the TIA Portal development software can trigger the PLC to move into RUN mode by power cycling it.

The steps to set the PLC to RUN upon startup are as follows:

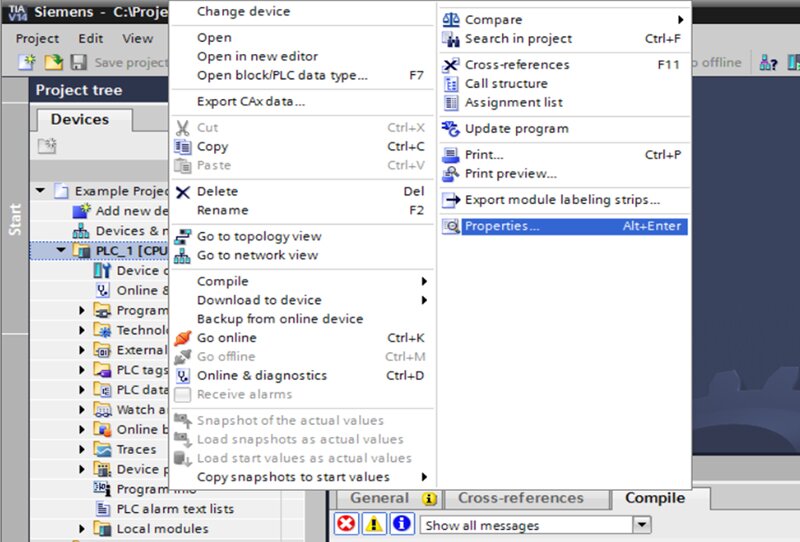

- Navigate to your PLC’s Properties

- Under the General Tab, select Startup, and change the drop down to “Warm restart - RUN”. Press OK.

Now, your PLC will go into RUN mode immediately upon startup!

PLC Web Server Accessibility

Configuring a web server for your Siemens PLC allows users to connect to the PLC over ethernet and change its Mode, perform basic monitoring operations, and access other useful control functions without needing access to the TIA Portal development software. Even if you don’t have time to make pages, just checking the box to make the web server accessible will allow you to perform fundamental functions like starting and stopping your PLC, viewing diagnostics, etc.

DMC already has a blog for this essential catch-all step! See instructions for setting up a web server.

Disable HMI Password Limit

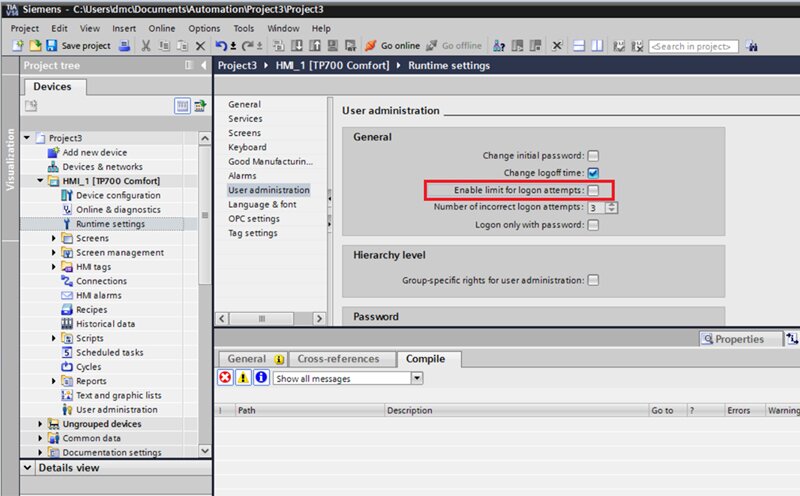

Perhaps the most significant Siemens project catch-all step is to disable the default password limit on your WinCC HMI. By Default, Siemens HMIs come with a limit of three logon attempts, meaning that, for password-protected user administrators, three consecutive incorrect password entries will permanently disable users from logging in to that account. The only solution to reset this after three attempts is to redownload the entire HMI project to the panel using TIA portal software with the HMI project file.

If you want your users to be able to have any access to their account after three logon attempts, you can disable this feature, or increase the number of times users can try before being permanently locked out.

To do this:

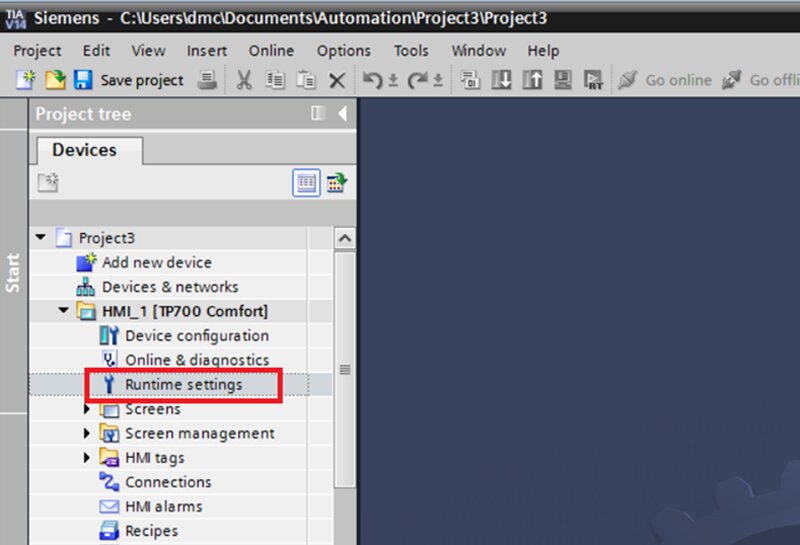

- Navigate to your HMI project’s Runtime properties by double-clicking Runtime Settings

- To disable the lockout feature, uncheck the “Enable limit for logon attempts”. To keep this permanent lockout but increase the number of allowed consecutive attempts, keep the box checked and increase the “Number of incorrect logon attempts” value.

With that box unchecked, user-administration will not be permanently disabled, no matter how many consecutive logins users try. Whew!

Conclusion

Following these three straight-forward steps before deploying your Siemens project can save you days of time in post-project support. Consider implementing these three quick solutions before finishing your project. We promise you’ll be glad you did!

Learn more about DMC's partnership with Siemens.

To see how we can help you get started on a project, check out our Siemens PLC programming services and contact us today!