DMC's Mad Science Drinxperiment with Siemens PLCs

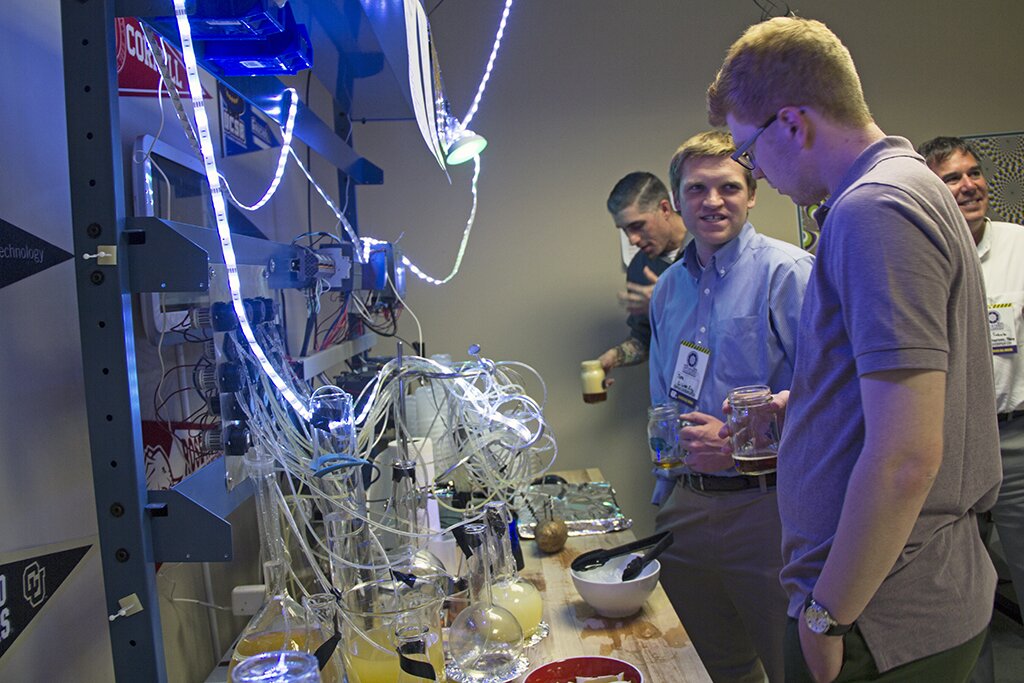

Last month, DMC Boston hosted our Mad Science Party.The event featured the Drinxperiment, an automatic bartender that uses 15 ingredients to mix up a variety of cocktails that guests can order using their smartphones. The Drinxperiment started as a last second idea for a Courier Day (half work day dedicated to DMC internal projects). With the help of nearly every DMC engineer in the Boston office, we were able to put the finishing touches on the machine just in time for the party.

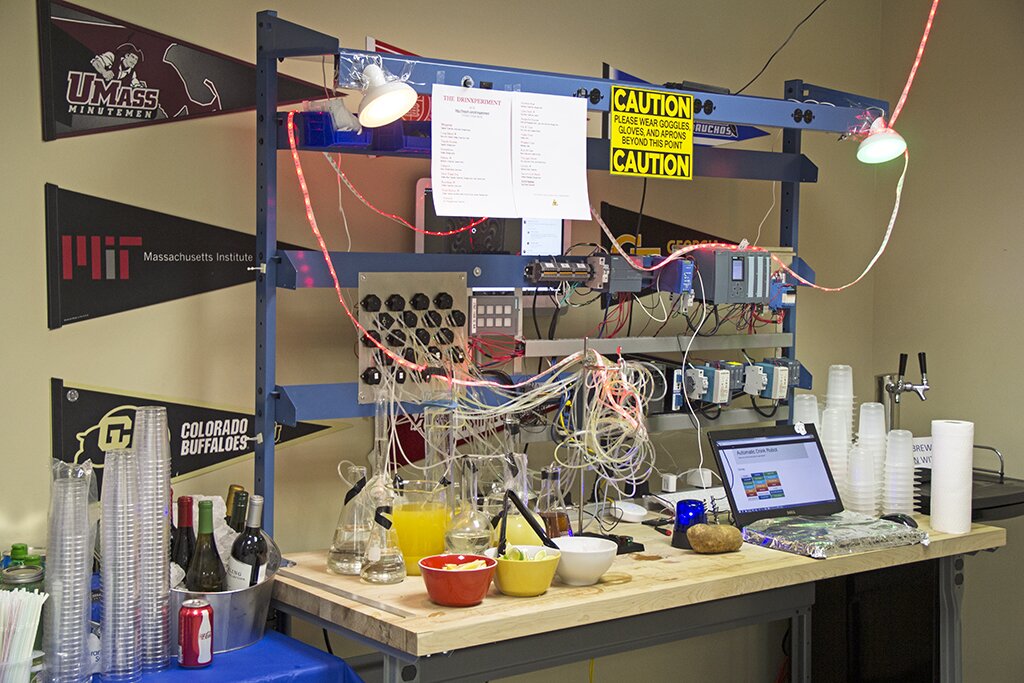

The Drinxperiment was constructed using a Siemens S7-1500 PLC, a Siemens S7-1200 PLC configured using I-Device, a Siemens KP8 key panel, standard 24V solid state relays, 12V peristaltic pumps, and two Philips Hue light bulbs. While the hardware configuration could have been much simpler, we used this project as an opportunity to showcase some of the capabilities of Siemens hardware. The S7-1500 in our lab was chosen as the main PLC because it had firmware release V4.0, which allows configuration of permissions for a generic user (ie-anyone with the link to the website is able to modify PLC tags and order a drink!). We incorporated the S7-1200 PLC as remote IO using I-Device in order to utilize the built in relay outputs. The KP8 key panel became our HMI for manual control that enabled us to prime the peristaltic pumps.

The Philips Hue lightbulbs have a built in controller and Wi-Fi bridge, which enabled us to change the bulb color using a standard HTTP post each time a guest ordered a drink. The user interface is a web page that is hosted on the S7-1500 PLC, which enables a user to read and modify PLC tags via HTTP posts. In other words, you can order a drink using your smartphone! All of the drink recipes were thoroughly tested by DMC experts prior to the party in order to maximize user satisfaction.

Learn more about DMC's Siemens S7 PLC programming expertise.

Comments

There are currently no comments, be the first to post one.