This blog will weigh some of the pros and cons of developing PLC solutions versus custom embedded solutions. The right solution for your project or product will depend on the features of the system, the number of units you need to produce, and the operating environment. This blog will attempt to assist you in this decision-making process. Additionally, the DMC team can help you determine what solution is right for you. This is not a new topic on the DMC blogs as we have written on this topic previously.

Background

A Programmable Logic Controller (PLC) is an industrial digital computer specifically designed for the control of manufacturing processes, such as assembly lines or robotic devices. PLCs are robust, reliable, and equipped with modular hardware and software to meet the demands of industrial environments. They are built to handle real-time operations and are commonly used in automation due to their ease of integration, scalability, and ability to withstand harsh conditions. PLC solutions are especially advantageous for applications requiring high uptime, where quick deployment and standardization are essential.

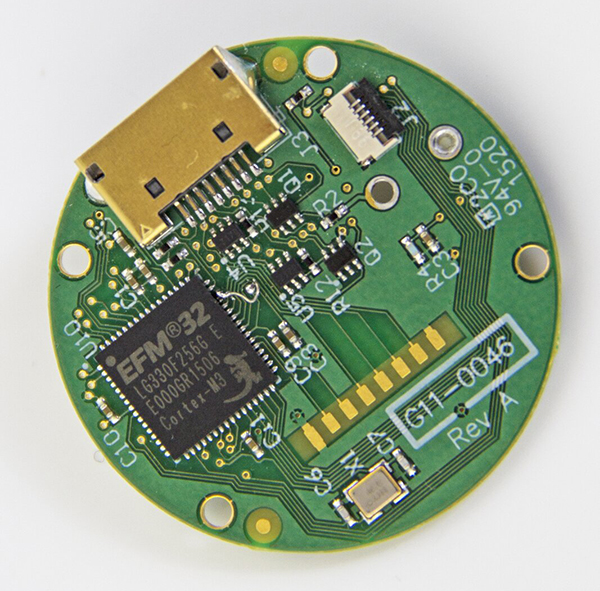

Figure 1 - Examples of PLCs

On the other hand, a custom embedded solution involves designing and developing custom electronics circuit boards and firmware tailored to the specific needs of a product or application. These solutions utilize microcontrollers combined with firmware optimized for the specific task. Because they are fully custom, embedded systems offer complete flexibility in functionality, size, power consumption, and integration, making them ideal for unique or high-performance requirements. However, they require significant engineering effort upfront, and their feasibility often depends on the scale of production and the complexity of the design.

Since embedded systems are extremely flexible, they can be designed to function like a PLC and control industrial processes in place of a standard off-the-shelf PLC.

Figure 2 - Low Power Custom Embedded Solution

Pros and Cons

The following table highlights some of the pros and cons of developing a custom PLC solution versus developing a custom embedded solution.

|

Criteria

|

PLC

|

Embedded

|

|

Non-Recurring Engineering (NRE) Cost

|

PLC solutions leverage existing off-the-shelf hardware, producing a lower cost solution in smaller volumes.

|

The NRE costs can be higher than PLC solutions due to designing custom electronics and writing custom software.

|

|

Per Unit Cost

|

PLC per unit costs can be high due to proprietary hardware and licensing fees.

|

Lowest per unit cost.

|

|

Ease of Development

|

PLCs come with ready-made hardware and software tailored for industrial automation applications. This can reduce the time to set up and deploy a solution.

|

Building a solution from scratch typically takes more time than deploying a PLC. Typically, one or more prototype PCBs are manufactured prior to manufacturing the final product.

|

|

Vendor Lock-in

|

Relying on a specific PLC manufacturer can make it challenging to switch to alternative platforms in the future.

|

Vendor lock-in can be avoided by leveraging open-source tools and components, providing long-term flexibility.

|

|

Reliability

|

PLCs are designed to operate in rugged industrial environments, and they support hardware with ruggedized I/O capabilities.

|

Additional testing and design iterations may be required to achieve the desired reliability targets.

|

|

Standardizations

|

A wide range of PLCs are available that adhere to specific industry standards and certifications (such as safety, explosion-proofing, etc.).

|

Standardization and certification requirements can be imposed on custom electronic designs being brought to the market to ensure that they will operate as expected and within agency-imposed requirements. However, that may require additional design effort and iterations.

|

|

Customization

|

PLCs may not offer the same level of customization as a custom embedded system, particularly for niche applications. Since PLCs are off-the-shelf components, standard configurations must be used.

|

Embedded solutions allow you to tailor the system to meet exact specifications, from hardware features to software behavior. Embedded solutions can be designed to maximize efficiency, size, and power consumption for specific applications.

|

|

Support Ecosystem

|

PLCs benefit from a large ecosystem of training, technical support, and community knowledge that can lead to reduced downtime and more troubleshooting capabilities.

|

Embedded solutions enable the final solution to leverage large open-source projects that have periodic security and feature updates and community support.

|

|

Scalability

|

Adding new features or connecting additional hardware is a straightforward process with modular PLCs.

|

Embedded solutions can include modular interfaces in their design; however, this needs to be incorporated into the overall system design at the outset of the project.

|

|

Assembly and Installation

|

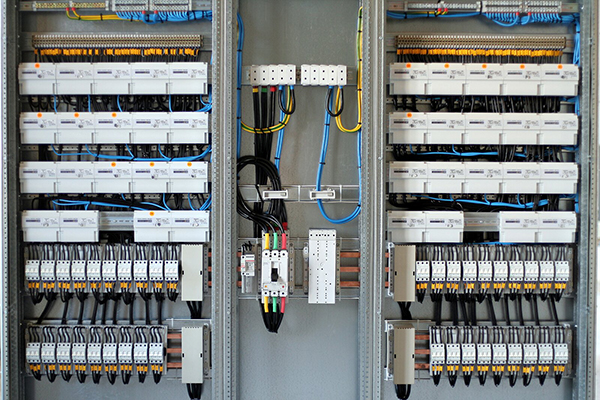

Customization is added by utilizing additional pieces of hardware that require custom wiring (see Figure 3 below).

|

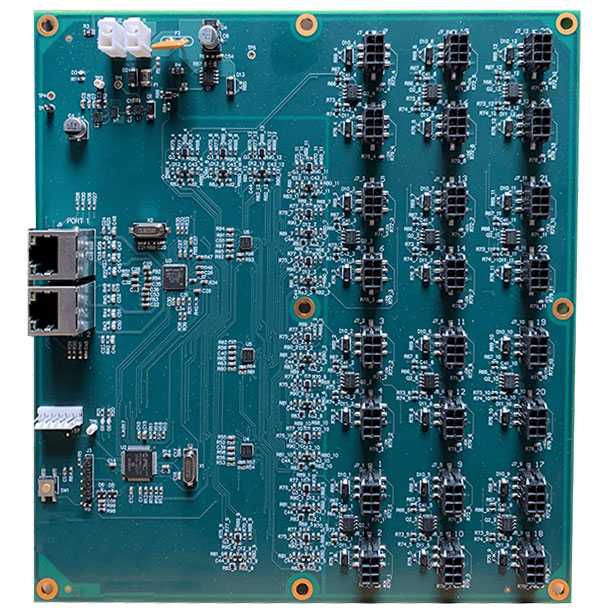

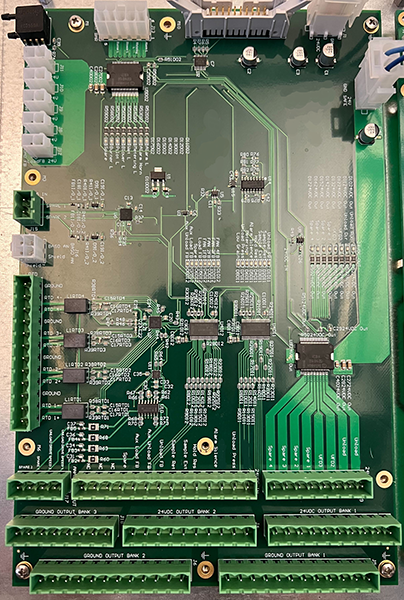

Due to having complete control over the design of the product, the system can be designed to have easy-to-use connector interfaces that make installation and manufacturing easier (see Figure 4 below).

|

|

Over-the-Air (OTA) Updates

|

Managing a fleet of PLC solutions can be challenging and is often done by manually establishing a remote connection to a PLC via a VPN gateway.

|

A custom smart backend solution can provide IOT OTA updates that are scheduled & controlled by a backend service. This can efficiently scale to an extremely large number of devices. See the DMC case study here.

|

|

Available System Memory

|

PLCs can have limited system memory; if more memory is needed, the system designers may be forced to move to a much larger PLC.

|

Memory can be extremely inexpensive to add to a custom embedded system. Many microprocessors have relatively large amounts of internal RAM (e.g., Nuvoton’s N9H30F63IEC has 64MB of internal RAM and can be purchased for an extremely low cost).

|

The images below compare an installation of a typical PLC panel and a custom embedded system PCB. Due to the customization, the size of the custom embedded system is significantly less than the PLC panel installation, and additionally, all the wiring is completed using custom cable harnesses.

|

|

|

|

Figure 3 - PLC Panel Installation

|

|

Figure 4 - Custom Embedded Solution with Dedicated Connectors for Inputs and Outputs

|

Another comparison can also be made between the 24V industrial IO outputs made with an off-the-shelf IO card and a custom embedded solution. These two examples can be seen below.

|

|

|

|

Figure 5 - PLC 24V IO Module

|

|

Figure 6 - Custom Embedded 24V IO Module

|

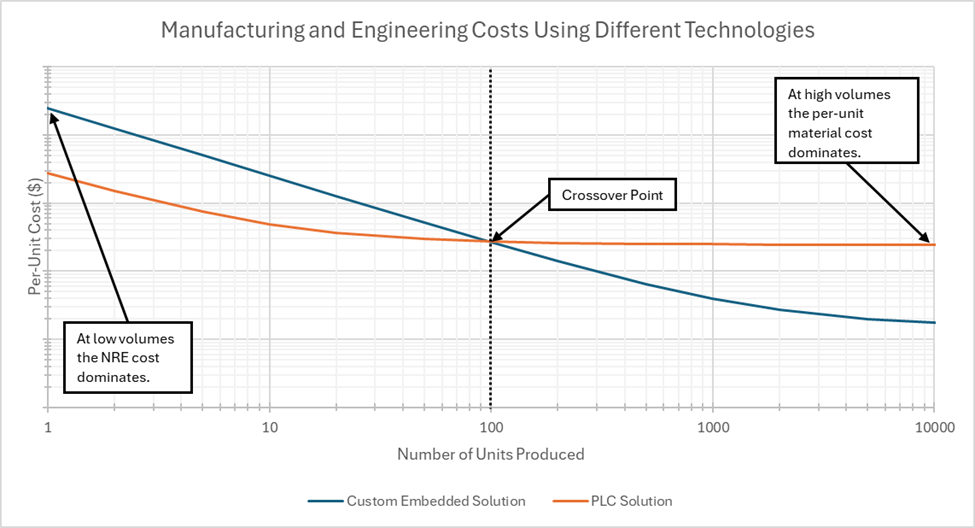

Comparing the Costs of Your Solution

Below is a cost analysis chart that illustrates how the per-unit costs of PLC solutions and custom embedded solutions could vary based on production volume. This chart is representative only, and the actual numbers and crossover points will be based on the specific requirements of your project. Initially, PLCs are more cost-effective because they are designed to operate in manufacturing environments, benefit from reusable code and tools, and feature modularity, all of which contribute to their efficiency and reduced deployment time. However, as production volumes increase, the lower per-unit material cost of custom embedded solutions begins to outweigh the upfront non-recurring engineering (NRE) costs. The crossover point represents where the custom solution becomes the more economical choice for higher-volume production.

Figure 7 - Per-Unit Manufacturing and Engineering Costs for PLC Solutions and Custom Embedded Solutions

DMC can help assess your design tradeoffs and help you make the right decision to pursue a PLC solution or Custom Embedded solution. We have teams with expertise in each of these areas and can engineer the optimal custom solution for your application.

Are you ready to take your project to the next level? Contact us today to learn more about our solutions and how we can help you achieve your goals.