NI Connect 2024 was a highlight event this year for the Test and Measurement industry that brought together major thought leaders to share insights, forge connections, and celebrate innovation. Let’s dive into the key takeaways!

Solving the Challenges of Battery Production and Remanufacturing Test

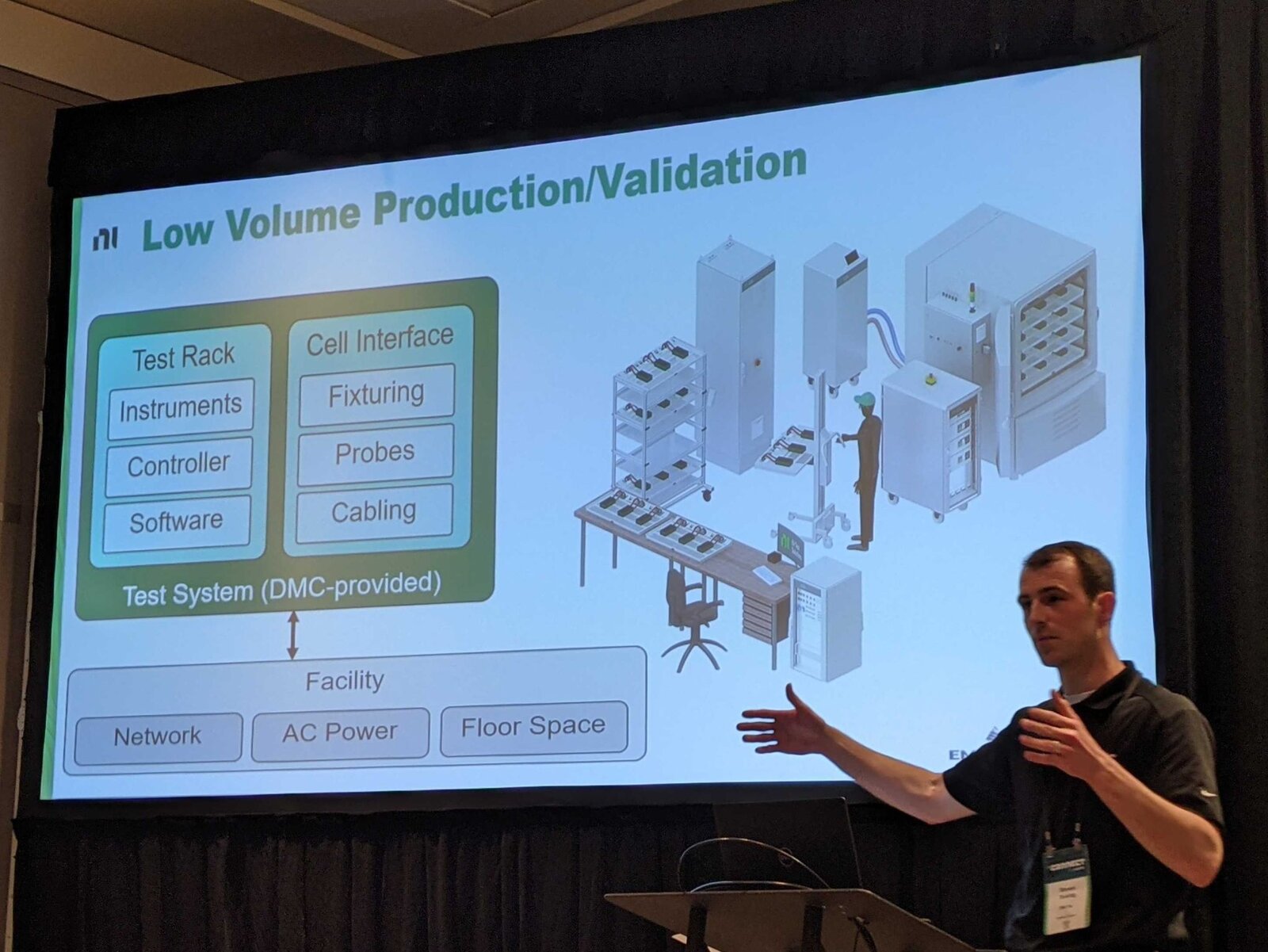

At NI Connect, DMC had the privilege of showcasing our cutting-edge battery production and remanufacturing test innovations at our exhibit in the Battery Production Test booth. We deeply appreciate the valuable input from our customers, which has allowed us to develop solutions that directly addresses the common pain points we frequently hear about from conference attendees. Scalability and openness to the test platform are core principles of DMC’s Battery Pack Test (BPT) solution, ensuring it meets the dynamic needs of the industry. If you are encountering similar challenges with you battery pack or module testing, explore our BPT Brochure and learn how we can assist you-from consulting to full system integration. You can also visit us on our battery testing webpage.

The DMC Battery Pack Test (BPT) System is designed by DMC’s Battery Test experts, leveraging almost two decades’ worth of battery test experience. It is a highly capable pack and module testing solution that enhances test coverage and scales with your organization. Some notable features include:

-

Open Platform: Built on NI TestStand, the BPT offers a truly open platform for managing test recipes that allows customers to fully own and adapt the solution to meet emerging technology requirements.

-

User-Centric Station Operation: Intuitive workflows ensure consistent daily production operation with minimal interaction with the software.

-

Role-Based Access Controls: Screen and feature access are controlled based on roles.

-

Flexible Configurations: The BPT can be deployed in one station rack module or decomposed into multiple station modules for optimized cycle times and throughput.

-

Complete Traceability: Continuous data acquisition (DAQ) provides traceability and visualization.

-

Integration with MES/SCADA Systems: Seamlessly integrates with your manufacturing execution system (MES) or supervisory control and data acquisition (SCADA) system.

-

Data Analytics via NI SystemLink or custom database plugin: Enables data analysis and insights.

-

IT-Synced User Permissions Management: Ensures secure access.

-

Soft-Front Panel HMIs: Allows manual device control and diagnostics.

DMC also took part in a joint presentation with NI on Advanced Battery Cell Testing Techniques, highlighting the work we're currently doing to help our customers scale battery cell testing with NI's latest technology.

Celebrating Partnerships and Connections

NI Connect 2024 was more than just a conference; it was a celebration of the strong bonds formed between colleagues, partners, and clients. Amidst great dinners, social events, and learning opportunities, the DMC team took a moment to recognize the strong partnership we’ve shared with NI for over 25 years. This partnership has been instrumental in helping our mutual customers solve challenging technical problems in a variety of industries. Some key themes to our partnership as I see them are:

Expertise and Solutions: DMC, recognized as an NI Preferred System Integrator, brings unparalleled NI ecosystem expertise to the table, especially LabVIEW programming. DMC’s role extends beyond writing code; we act as consultants, advising on hardware choices and anticipating future needs. NI’s hardware product offerings combined with DMC’s expertise and software solutions helps our customers get to market faster.

Investments in Product Offerings: NI continues to invest in both hardware and software, enhancing test workflows and leveraging test data with their latest emphasis on the LabVIEW+ Suite. NI’s renewed commitment to their software platforms provides clarity on areas of NI’s investment and enables DMC to focus on forward-looking solutions for our customers, knowing that we have the investment and backing of NI to take on the next challenge. In particular, NI’s focus on AI is opening new doors for the future of what test engineering can look like, and DMC is excited for the new opportunities ahead.

Collaborative Spirit: NI Connect 2024 exemplified the collaborative spirit that drives the industry forward. The strong partnership between NI and DMC is a testament to this spirit, resulting in innovative solutions for customers. NI’s Battery Test Solution for Pack Validation and DMC’s Battery Production Test (BPT) solution are recent examples of DMC and NI collaboration.

Thought Leadership and Educational Lectures: A key feature of NI Connect 2024 was the array of lectures on cutting-edge innovations, providing a platform for thought leadership within the industry. These sessions were not just educational but inspirational at times, offering a glimpse into the technological advancements that are shaping our world.

NI Focus on Generative AI

Notably, several exciting AI technology integrations were discussed, highlighting how NI is focusing on leveraging AI as a competitive advantage in their product offerings, which will help our customers leverage this cutting edge technology to enhance their business performance. Here are some highlights:

Analytics Tools (AI and ML): The use of artificial intelligence (AI) and machine learning (ML) in test processes was a hot topic this year. Attendees discovered how these tools can improve yield, enhance product quality, and drive innovation. NI continues to invest in its new AI assistant, NIGEL, expanding capabilities and planning a roadmap that ensures you can leverage the power of AI wherever you need: from the cloud to the edge and anywhere in between.

Effective Test Data Management: Companies learned strategies for optimizing test data management. By efficiently handling large volumes of data, organizations can make informed decisions and drive better outcomes. Tools like NI SystemLink greatly simplify this task. DMC has lots of experience using SystemLink and can attest to its impact on our customers' workflows, data analytics, and systems management. AI is certain to play a large role in transforming the utility of this data and rapidly accerating data analysis capabilities for our customers.

Python/LabVIEW Integration: Attendees explored Python/LabVIEW integration, allowing seamless collaboration between these two powerful programming languages. This integration streamlines test development and data analysis, enhancing overall efficiency and productivity. Both Python and LabVIEW are getting lots of AI integration investment, making it easier for teams to build sophisticated software in record time. DMC’s multiple service areas, including Test & Measurement and Application Development frequently work together on projects, bringing the best solutions from multiple technologies like LabVIEW and Python together into an integrated solution the leverages the advantages of both. You can check out some of our latest thinking on using text based languages for your test projects here.

Final Thoughts

NI Connect 2024 was a testament to the power of collaboration and innovation. It was an event where industry leaders could share their vision for the future and where partnerships were strengthened. As we reflect on the success of this year's conference, we are reminded of the endless possibilities that lie ahead for technology and innovation. The DMC team, along with our partners at NI, are at the forefront of this journey, providing our expertise and enthusiasm to our customers to help them solve their most challenging problems.

Thanks for reading! We hope to see you next year at NI Connect 2025 in Fort Worth, Texas.

Do you have a challenging problem you are trying to solve? We would love to help you too – just get in touch! https://www.dmcinfo.com/contact