Data is the currency in the world of technology. This incentivizes creating systems of data capture, storage, and search. In the automation space, many industries rely heavily on data to record and improve their manufacturing process.

Five Levels of Automation

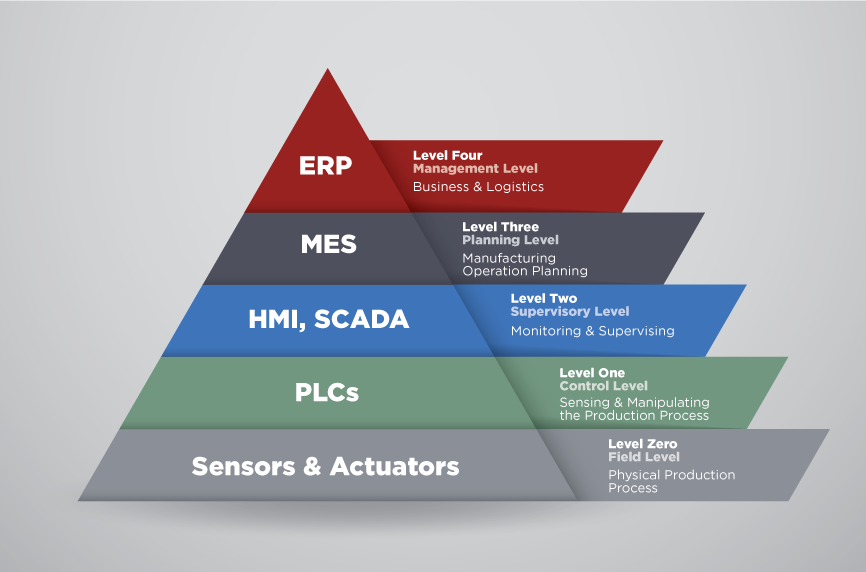

According to the ISA-95 standards there are five levels of automation (also referred to as the “Automation Pyramid”. Those are:

- Level 4: Enterprise management (ERP)

- Level 3: Manufacturing operations planning (MES and MOM)

- Level 2: Supervising (HMI and SCADA)

- Level 1: Control (PLCs)

- Level 0: Field devices

Purpose of the MES Layer

This blog series will be focusing on Manufacturing Execution Systems (MES) which lives in Level 3. The main intent of the MES layer is to act as a messenger between the ERP and the SCADA and PLC/HMI layers. For instance, in a car manufacturing firm, the ERP will have a customer order for 10 blue cars along with the design of the car model they want to build. The SCADA system will send commands and recipe data to the PLCs and acquire data while the PLCs are sending commands to the devices assembling the car.

In this system, the missing functionality is taking the customer order information, scheduling it to the applicable production lines, and sending the car model specific data that is in the ERP to the control layer. This task is typically completed by the MES layer. The MES layer takes in an idea of a product and then creates a plan to execute it in the manufacturing environment.

The basic building blocks of a typical Manufacturing Execution System include:

- Create Work Orders, Part Numbers, and Recipes

- Schedule work orders

- Material tracking and traceability

- Overall equipment effectiveness (OEE)

- Downtime tracking

- Quality control and statistical process control (SPC)

- Digital work instructions

- Tracking consumption of inventory and relaying that information to the ERP or WMS

- Labor management

The lines between the different ISA-95 levels can sometimes be blurred and functionality that may be a traditional MES feature you may see in the ERP or SCADA layers. This is normal and gives you the flexibility to design your systems to best fit your processes. For example, sometimes the ERP will have work orders or SCADA may calculate OEE.

MES Platforms

There are multiple industry-wide used platforms for MES, each with their own set of features and capabilities. Some common platforms are:

Sepasoft

Sepasoft offers real-time visibility into the operations of the plant floor to help improve efficiency and reduce costs.

Sepasoft MES Solution for Food Processing Facility

DMC developed a custom Manufacturing Execution System (MES) application for a large manufacturer in the food and beverage industry to optimize and automate their system.

FactoryTalk

FactoryTalk is an industrial automation software from Rockwell Automation that improves plant efficiency and productivity.

Factory-Wide MES Data Collection System

DMC implemented an extensive data collection system for a client in the confectionary industry offering the client a closer lens into their processes with automated data aggregation.

Ignition

Ignition is a development environment from Inductive Automation that allows you to create an industrial software application. It's one of the fastest growing HMI/SCADA platforms today.

Optimizing Load Times in Ignition Perspective

Ensure that screens load fast and actions are snappy when using Ignition Perspective to create bigger and better projects.

Creating Dynamic Ignition Perspective Projects, Part One: Bindings and Transforms

Learn how to start a Perspective view in Ignition, create bindings to tags and properties, and use binding transforms to correctly display that information.

Creating Dynamic Ignition Perspective Projects, Part 2: Button Event Actions

Learn how to use button events to write to component properties and tags in Ignition.

Creating Dynamic Ignition Perspective Projects, Part 3: Embedded Views and Flex Containers

Learn how to combine objects into an embedded view in Ignitionand create a dynamic layout using a flex repeater.

Creating Dynamic Ignition Perspective Projects, Part 4: Parameters, Indirect Bindings, and Flex Repeaters

Learn how to add parameters to your embedded view in Ignition, drive indirect tag bindings, and maximize our layout efficiency in a flex repeater.

Learn more about DMC's MES Programming services and contact us for your next project.